AI in Condition Monitoring

SeeNous can revolutionize maintenance and promote experts engagement and accessibility, to relieve overburdened maintenance systems

AI as an assistant for CM

Vibration-based diagnosis and recommended corrective actions for machine failures through a combination of AI and human expertise

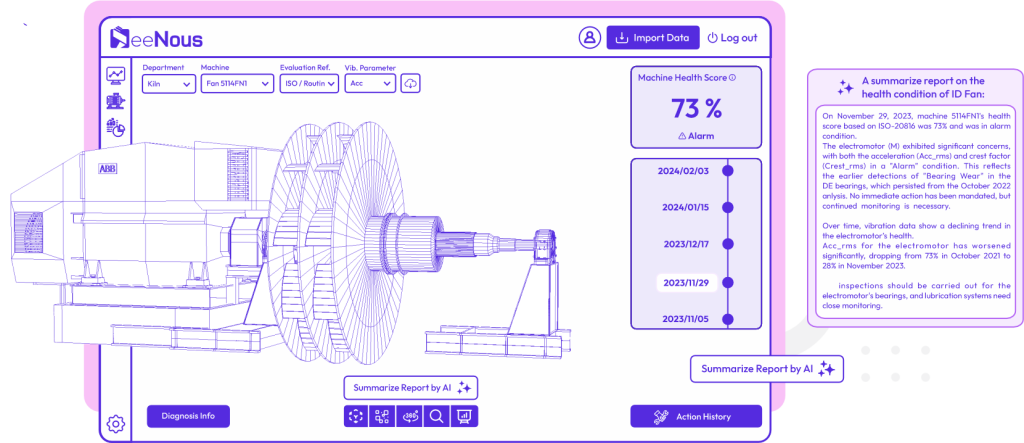

Summarize Report by AI

The SeeNous generative AI produces real-time text reports on the health status of your machines

Digital Twin–Powered Dashboard

Explainable AI & Collaborative Action

Actionable, explainable recommendations to drive repairs

Cause-oriented analysis for precise fault identification (e.g., imbalance, looseness, bearing).

Shareable snapshots and reports to align teams and accelerate decisions.

Explainable AI recommendations make the decision path transparent — turning predictive insights into practical maintenance actions.

Digital Twin–Powered Dashboard

Interactive 3D Exploration

Interactive 3D views for fast root-cause detection

Explore machine components in a realistic digital twin.

Drill into parts and pinpoint sources of abnormal vibration.

Visual navigation shortens investigation time and reveals hidden issues.

Digital Twin–Powered Dashboard

Contextualized Insights & Alerts

Data and alerts, presented where they matter

Overlaid charts, thresholds, and trend lines directly on the 3D model.

Immediate context for each alert so experts see what and where at a glance.

Time-series visualization enables quick comparison of past and present behavior.

Digital Twin–Powered Dashboard

Explainable AI & Collaborative Action

Actionable, explainable recommendations to drive repairs

Cause-oriented analysis for precise fault identification (e.g., imbalance, looseness, bearing).

Shareable snapshots and reports to align teams and accelerate decisions.

Explainable AI recommendations make the decision path transparent — turning predictive insights into practical maintenance actions.

Digital Twin–Powered Dashboard

Interactive 3D Exploration

Interactive 3D views for fast root-cause detection

Explore machine components in a realistic digital twin.

Drill into parts and pinpoint sources of abnormal vibration.

Visual navigation shortens investigation time and reveals hidden issues.

Testimonials

?How do we support Factory Production

by offering AI-driven Predictive Maintenance tools that minimize downtime and optimize Machines performance

01

Cloud Access to Data and Reports

Our technology remotely connects machinery with experts, enabling greater access to monitoring from any location. This enhances efficiency for condition monitoring (CM) professionals. Additionally, data can be manually entered from various vibration data collectors.

02

Prediction of Machine Failure with AI

Powered by artificial intelligence, SeeNous assists your experts in diagnosing and predicting machine failures. It also recommends corrective actions to address issues, significantly reducing the time needed for repairs. SeeNous AI is fully explainable, providing clear insights into the reasoning behind its predictions.

03

Better insights, Smarter Care

3D models, mirroring your machine, help experts develop a more comprehensive understanding of its condition. We support expert decision-making by providing real-time visibility into machine data through a web-based dashboard. The dashboard includes threshold-based flagging systems, trend analysis, and 3D visualization for deeper insights.”

We’re global

We are not constrained by geography — for many roles at SeeNous, our brilliant team can choose to work wherever they have an Internet connection. Our HQ is located in Mashhad Innovation Factory, Iran.